Description

The VF-Engineering designers set about designing the billet supercharger mounting bracket with CAD software creating solid models of parts to be CNC manufactured. The bracket was designed to utilize OEM bolt patterns and requires no alteration or relocation of any engine parts to be fitted. Made from 6061-Tx aircraft grade aluminum the bracket mounts to factory machined surface points on the aluminum engine block for a precision fit.

A V3 model Vortech Engineering supercharger unit was chosen after consultation with Vortech engineers and matching the engine’s volumetric efficiency with supercharger compressor maps. The V3 unit contains helical-cut gears for super quite performance – virtually silent with the engine compartment lid closed. The V3 supercharger has a 20psi and 1000cfm maximum capacity and is an over-engineered part for this Porsche application which is geared to produce a conservative 6psi in the engine’s intake manifold.

The Vortech air to water intercooler (charge cooler) was integrated into the tight fit engine bay as means of reducing charged induction (boost) temperatures. Lower charge temperatures promote engine safety by reducing knock and improving the quality of the combustion cycle. Air charge (boost) from the supercharger is directed through the chargecooler core before entering the throttle body. The cooler core contains isolated channels circulating with water from a separate self contained system cooled by its own radiator. VF-Engineering integrated a Porsche OEM front radiator and front bumper vents into the kit. Water is circulated by means of an added OEM Bosch water pump through OEM Good Year water lines. Intake air temperatures in the manifold were measured to be approx 140 deg F even with ;spirited; driving at 118 deg F ambient temperatures in Arizona desert conditions mid-Summer. This dramatic drop in charge temperature helps the 996 create consistent power. For added safety the chargecooler is designed to perform continuously whilst the ignition is on.

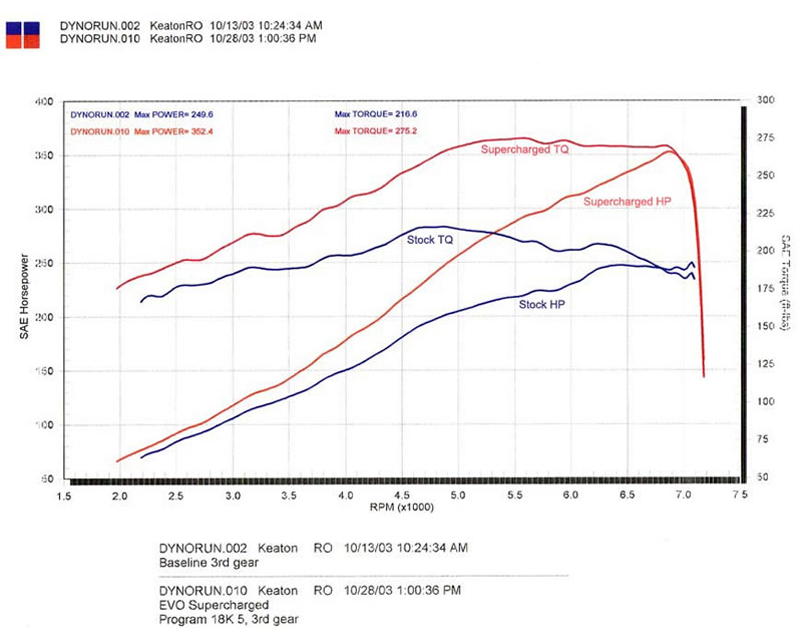

With all major components in place the head of R&D at VF-Engineering, set about shaping the air ducts from the filter to the throttle body. The intake pipe is specially tuned for its air flow characteristics and pressure relief system. Production pipes are manufactured from a lightweight molded high temperature polymer. The thermal insulating properties of the plastic pipes prevent heat transfer into the cooled charged air traveling inside them. Engine management software was by written by VF with extensive testing performed on independent test cars. Multiple factors such as charge air temperatures, ignition timing, fuel trims, maps and injector performance were taken into account. The Carrera 2 and 4 test vehicles were extensively dynoed on the VF 4WD Mustang and monitored for wide band air fuel ratios at load levels often greater than would be experienced on the road. The results are an increase of 120 horsepower and 80 ft.lbs of fully useable torque.

Specifications:

6.0 PSI

+ 150 Horsepower

+ 87 lb/ft torque

Features:

Custom tuned software

Vortech V3 SQ trim black supercharger

CNC machined 6061 aluminum bracket system

OEM idler pullies

OEM High flow fuel injectors

Custom molded polypropylene ducting

Bosch overrun bypass valve system

Custom crank case ventilation system

4-ply silicon couplers with OEM screw clamps

CNC oil fittings with high pressure OEM oil lines

Replacement OEM serpentine belt

K&N induction filter with cold air intake and optional air box

Comprehensive installation CD-ROM

Precision Made in California, USA

1 year unlimited mileage warranty on the product only

Click Here for Installation Instructions

Reviews

There are no reviews yet.